Planning Your Engine

Before for you can start work, it's critical that you have some sort of plan in place in order to be able to choose components that work together and are suitable for the intended use. But before you even start planning you should work out how much power is needed to be competitive, and roughly what sort of rev range will be associated with that power level. If, for example, it turns out that you need 500hp or that the powerband will be only 1500rpm wide then at least you'll know not to waste any more time and money trying to build a winner from a 202 and an Aussie 4 speed...

Some of the things you'll need to address are:

- The anticipated usable rev range of the engine - be realistic and don't be tempted to sacrifice too much power lower in the rev range for big horsepower numbers. By the time you get into the juicy part of the powerband your competition may already have passed you. What you are after is the maximum average horsepower over the usable rev range, with particular emphasis on strength at the lower end of the range. Always remember that to get to the top end you first have to accelerate through the lower speeds. The engine with the most peak horsepower isn't necessarily the fastest one.

- Durability requirements - a street engine that requires monthly rebuilds is obviously useless. Conversely, a conservatively built engine that lasts for 200,000km is unlikely to win many drag races

- Practicality on the street - If it's a street car you're building, don't sacrifice all for peak horsepower. An engine with no usable power under 4000rpm in a street car will be extremely unpleasant. Similarly, engines that require ridiculously high convertor stall speeds will be painful to live with day to day.

- Legal and class rule requirements

- The Budget - This is one area where the final figure is very likely to be much much higher than the original estimate. Spend as much time as necessary on this to come up with a fully detailed costing of the project.

Be particularly careful about determining the usable rev range.

At the top end maximum revs will be largely determined by the

strength of the reciprocating components, and these in turn may be

limited by your budget. The lower end of the rev range will be set

by the available gear ratios and/or the stall speed of the

convertor. You can use this simple formula to work out the rpm drop

at gear changes:

rpm=(gear ratio divided by ratio of previous gear) x maximum

rpm

For example, let's say we have a gearbox where 1st gear is 3.05:1

and 2nd is 2.19:1. Dividing 2.19 by 3.05 gives us 0.718. If we now

multiply our maximum rpm - say 7500 - by this figure we get

5385rpm, the speed the engine will be doing when we change into

second. You can calculate the rev range for each gear like this,

but normally the biggest drop in revs will be in the lowest gears.

In our example, we would want to build our engine to make the

highest average horsepower possible from 5300 odd rpm to our

maximum of 7500rpm. This of course assumes that we can maintain the

revs in this range in real world driving, and that it's possible to

launch the car from a standing start with this powerband. In

reality, it may be necessary to use a bottom rev limit

significantly lower than the calculated figure to maintain

driveability. Clearly then, an engine designed to run with a close

ratio six speed will be hopeless if coupled to a 3 speed box.. It

might be tempting to use something like a Trimatic with a convertor

the size of a doughnut to keep the revs up; just be aware that very

high stall speeds

sap quite a few horsepower at the top end, horsepower that we

can ill-afford to lose with our little sixes.

Once you've determined what rev range you'll be building for, you can start to select components that are appropriate for this range. It is essential that all the components are correctly sized, eg. if you are building an engine to make power from 2500 to 6000 rpm then the camshaft, porting, carb and manifolding, exhaust and compression ratio will all have to be closely matched to this target.

Useful Planning Tools

|

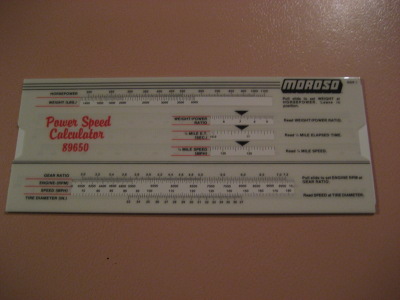

| A Moroso Power/Speed Calculator. |

There are a couple of tools you might find useful when planning and designing your engine. The first one, Moroso's Power/Speed calculator is practically indispensable for drag racing projects. For a given car weight and horsepower, it will show what E.T. and terminal speed can be reasonably expected. Or alternatively - and more useful for our purposes - it can show what horsepower will be required to propel our car to a nominated ET or speed. As well as this it has other functions for calculating compression ratios, gear ratios etc. A very highly recommended tool, and cheap too.

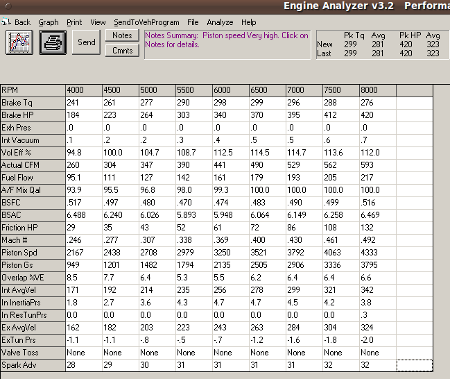

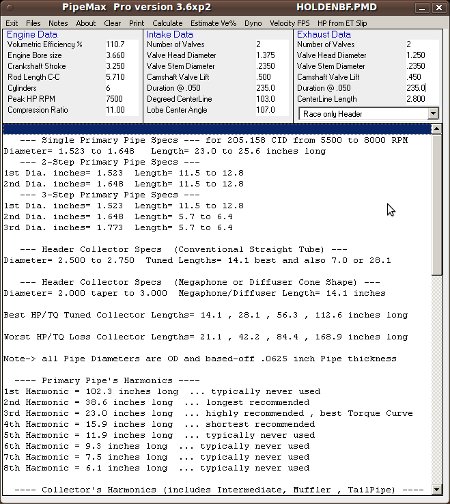

Engine simulation software is also useful for planning and designing your engine. Maybe not as essential (or cheap) as the Moroso slide rule but handy nonetheless. While there is a multitude of software packages ranging from the cheap'n'simple to the incredibly detailed (and expensive) there are two programs in particular I'd recommend for the non-professional builder. These are Engine Analyzer (and it's slightly more detailed sibling Engine Analyzer Pro) and PipeMax. Both these will help enormously in the selection and sizing of components. The predicted horsepower figures mightn't be 100% accurate but generally they are very close. Engine Analyzer tends to be optimistic with the projected horsepower figures, while PipeMax seems to be very close but perhaps a tad conservative. PipeMax is especially good for experimenting with different intake and exhaust dimensions, and gives much more detail in this department. Both programs can also help with calculating static and dynamic compression ratios, fuel rates, timing and many other parameters. If I had to choose between them I'd definitely go for PipeMax every time; it's interface mightn't be as slick as some of the others but it seems to provide very consistent results. Actually the cost of the software is minimal in comparison with the cost of building an engine, and the money is likely to be recouped many times over through the reduction of real-world trial-and-error parts testing. Again, very highly recommended to have before any actual work is started. One of the nice things about both the programs mentioned is that if (like me) you're a Linux user both will run nicely under Wine. See the links section for their web addresses.

|

| Screenshot of Engine Analyzers' performance calculation window showing the fairly comprehensive output. |

|

| Screenshot of PipeMax showing a small portion of the available output data. |

- Previous page: Characteristics and Limitations

- Table of Contents

- Next page: Choosing a Displacement and block