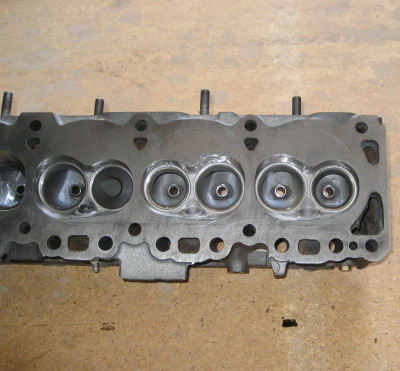

Unshrouding the Valves

In both types of head the valves are very badly shrouded, and the bigger the valve you use, the worse it is shrouded. But with a stock or very mildly modified head the shrouding is a surprisingly minor problem - the stock ports flow so badly that unshrouding the valves has a negligible effect on flow. Once the ports have been tidied up though, further gains are definitely possible through unshrouding.

At the outer side of the chamber it is impossible to get much more than about 0.1" of clearance with big valves, so the shrouding effect can never be entirely eliminated. On the port side of the chamber it's fairly easy to grind some clearance but to get the ideal means removing lots of material and therefore grinding into the water jacket is a risk. The spark plug side of the head is where most of the flow will be at higher speeds, and again a lot of material will have to be removed so be cautious and study your cut-up head carefully. Use a head gasket as a guide to how far you can take the chamber wall. Of course this makes the step or ledge at the top of the cylinder bigger but the benefits of reduced shrouding far outweigh the increased turbulence from the ledge. Ideally the wall immediately around the valve head will slope back about 45 degrees, so that the distance from the wall to the valve is always about the same as the distance the valve is off its seat. In practice you mightn't be quite able to achieve this but it's critical that you get it as good as you possibly can. If you get the chance to run tests on a flow bench you will see that even minute increases in the distance from wall to valve will improve the flow (with a good port). If you are fitting oversize valves consider using eccentric valve guides to shift the valve towards the centre of the cylinder. Even if you only shift the valve say 0.040" to 0.060" you will pick up useful gains in flow. Again though, the water jackets around the bowls may be a limiting factor.

|

| Unshrouding large valves requires removing lots of material so take care to avoid making the chamber walls too thin. |

Relocating the Head

You'll probably find that the valve will still be slightly shrouded on the spark plug side even if you grind back to the gasket. What you can do to improve this is move the head towards the manifold side of the block by about 2mm. You will need to elongate the dowel holes in the head (don't just yank the pins out because they are needed to accurately locate the gasket) and also the bolt holes. Provided you don't get carried away you won't have too many dramas getting the water holes lined up, but don't forget to check pushrod clearance through the head. The extra couple of millimetres that can be ground from the sparkplug side wall will improve flow slightly and will also help enable further gains from port work. Realistically though, the gains will be very small.